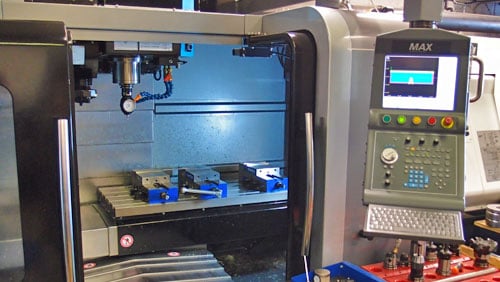

CNC engineering is an integral part of the majority of equipment manufacturing processes in numerous industries, including oil, gas, power, pharmaceutical, and healthcare manufacturing.

When it comes to common metals, such as mild steel or aluminium, CNC turning and milling don’t pose many problems. Meanwhile, specialist materials such as some plastics, including PVC or nylons and metals such as lead-bronze or harder stainless steels, require a more specialist approach without which problems may occur. Thankfully, with the right equipment at hand, CNC machining can be applied to virtually any material, including the most problematic.

Precision CNC Engineering And Plastics

Even though the tools and the overall approach are similar, turning and milling plastics is somewhat different from machining metals.

Before manufacturing spare parts using plastic it’s important to make a thorough investigation of the specifications and tolerances of the product. The techniques for achieving the right results using plastic instead of metal may vary.

When it comes to CNC machining, the main difference between common metals and plastics is their reaction to temperatures. Plastics and thermal plastics may be substantially affected by temperature and ambient humidity during the manufacturing process.

Plastics can perform in a different manner when the operator is removing material from the machine, requiring creativity coupled with experience and skill. When choosing a third-party spare parts manufacturer, it’s important to check which materials it specialises in.

CNC Machining And Teflon (PTFE)

Teflon is a commonly used trade name for PTFE, which is a plastic with excellent low friction and heat resistant qualities. However, it expands quickly when heated, which makes it one of the trickiest materials for CNC machine specialists, as it lacks the stability of common metals. Hitting fine tolerances on size is very difficult if the material is expanding and then contracting. While manufacturing a product out of Teflon, the material must be kept cool and cutting tools must be exceptionally sharp to avoid the material distorting. If handled improperly, it can weld to the cutting tool, damaging the CNC machine.

Experienced operators know several tricks to help them deal with Teflon such as quick feeds and air or coolant blasting. In the end, with a professional approach Teflon spare parts can turn out as well as common metal products.

CNC Engineering Bronze And Lead

Bronze and lead are non-ferrous metals. They are softer than ferrous metals - such as steel - and melt at a much lower temperature. These properties make them easier to machine but only if you know the right approach. The lower melting point combined with the high temperatures during CNC machining can easily lead to the operator exceeding some fine tolerances.

Lead-bronze alloys are highly corrosion-resistant and have excellent low friction qualities. As a result, they are widely used in many applications. A good CNC engineering specialist will be practiced in machining non-ferrous metals.

The right equipment also plays a big role in successfully machining non-ferrous metals. Not all types of machine provide the right environment for the temperature-sensitive materials.

CNC Machining Specialists

At Woodley Engineering, we specialise in working with numerous materials including plastics, PVC, Teflon (PTFE), non-ferrous and ferrous metals. We have a team of experienced machine operators who all use their experience and creativity to achieve precision results. For more information about our services, please click here to download the free Precision Engineering Guide.